Pump Maintenance Tips: How to Winterize a Pressure Washer

Shawn Glover, VP of Sales, Oct 12, 2021

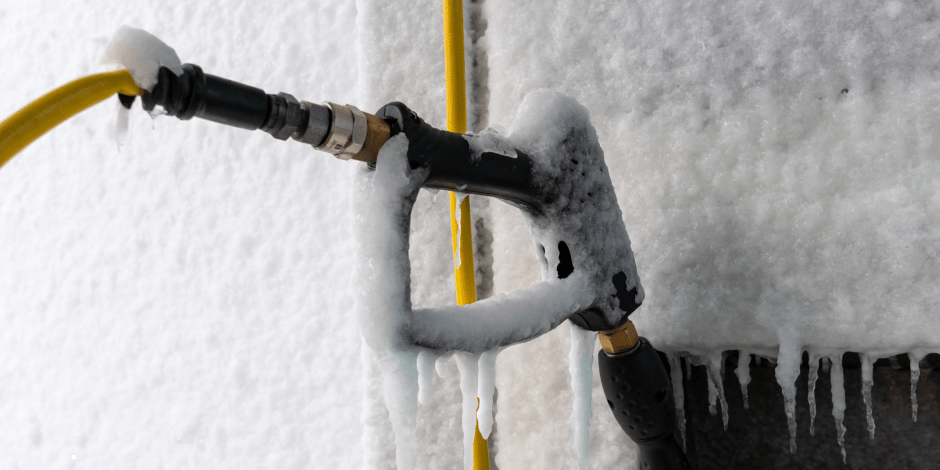

For much of the U.S., the winter months are accompanied by cold weather and freezing temperatures, bringing a halt or significantly slow down to many pressure washer operations. Before storing your pump equipment, it’s important to make sure you take steps to winterize pressure washers to protect them from the elements and impact of sitting idle for prolonged periods.

If your equipment will be stored for more than 30 days and you’re wondering how to winterize a pressure washer pump so that it operates properly when you bring it out of storage in spring, use these step-by-step tips.

1. Completely Drain Reservoir

The freeze/thaw cycles that can occur during the winter months can cause any remaining liquids to expand and contract, potentially damaging a pump beyond repair. Do not leave any liquid or cleaning solution in the tank or plumbing. Turn the pressure washer on for about a minute at the lowest pressure possible and squeeze the trigger to flush any detergent or water supply out of the lines.

2. Blow Out Plumbing and Hose Lines

Disconnect the spray gun, wand assembly, and high-pressure hoses, draining as much liquid as possible. Even after draining a system, a small amount of fluid will likely remain in the plumbing system. Use an air compressor to blow out any remaining liquid.

3. Rinse the System with Antifreeze

Consider rinsing the system with a small amount of antifreeze before winter to help keep components from freezing. Be sure to once again blow out any remaining fluid.

4. Clean Filters

Remove the pump filters and clean any particulates from the filter bowl or strainer. Ensure there is no residue buildup on the metal mesh screen.

5. Clean Nozzles

Detach nozzles and clean the orifice, removing any buildup or deposits to prevent corrosion.

6. Protect From Rodents Damage

It’s amazing how much damage small rodents can cause to wiring and other pressure washer components. Use deterrents, traps, and other methods to prevent rodent damage, similar to how you might protect a vehicle in a garage.

7. Disconnect the Battery

If your pump is a battery operated system, disconnect the battery to reduce the likelihood of it becoming fully drained.

8. Take Extra Steps for Gas-Powered Pumps

If your pump operates using a fuel system, drain all gasoline. Alternatively, you could add a fuel stabilizer to the fuel tank and run the engine for a few minutes to help it circulate throughout the fuel lines. Also, disconnect the spark plug wires and replace spark plugs.

9. Clean Exposed Surfaces

Use a damp cloth to clean visible dust, debris, and dirt from all exterior surfaces and crevices to prevent rust and keep your pump system and housing looking like new.

10. Store in a Dry Location

Storing your pressure washer in a clean, dry location helps to minimize potential corrosion or damage caused by the elements. Consider using a cover to protect it from settling dust. Ideally, keep your pump equipment in a location that does not freeze.

11. Follow Pump Manufacturer Recommendations

What happens if you don’t properly winterize your pressure washer pump before long-term storage? If a pump isn’t properly winterized, damage could occur to internal plumbing, hoses, seals, and other components, leading to possible pump failure.

When all is said and done, the best way to ensure you’re properly storing and maintaining your pump equipment is to check with your pump manufacturer for their recommendations. In general, battery-powered or electric pressure washers will have far fewer maintenance requirements than gas-operated pumps. Electric pumps have fewer parts and simpler configurations, meaning less can go wrong.

To view an example of how to configure an electric plunger pump into a system, check out our visual guide below. Contact the pump experts at Pumptec to learn more about our durable pump solutions for pressure wash applications and other industries, and see how the right pump can save you time and money.