We recently acquired Triple R Specialty!

Read the story about why we joined forces and what it means for hydrostatic testing customers.

We recently acquired Triple R Specialty!

Read the story about why we joined forces and what it means for hydrostatic testing customers.

Superabrasive manufactures diamond tools that are known for their durability, efficiency, versatility, and user-friendliness. Its most popular product line is LAVINA which includes grinding and polishing machines, burnishers, dust extractors, and diamond tools for nearly any floor application from prep to maintenance. These electric and propane units are primarily used for concrete, natural stone, terrazzo, and overlays.

One of the challenges of grinding these types of flooring materials is eliminating the harmful silica dust that is created. Small particles become airborne and prolonged exposure has been associated with lung damage. To protect workers, OSHA enacted regulations requiring users of indoor concrete grinding equipment to utilize some form of dust suppression to control silica dust particles with a median size of 10 microns or less.

Superabrasive initially considered using a HEPA vacuum system to collect the dust particles and comply with OSHA standards. However, while the form factor would work with their LAVINA line, HEPA systems struggle to capture all of the 4-10 median dust particles. OSHA regulations specify that workers not be exposed to more than 50 micrograms of silica dust per cubic meter of air within in an eight-hour period.

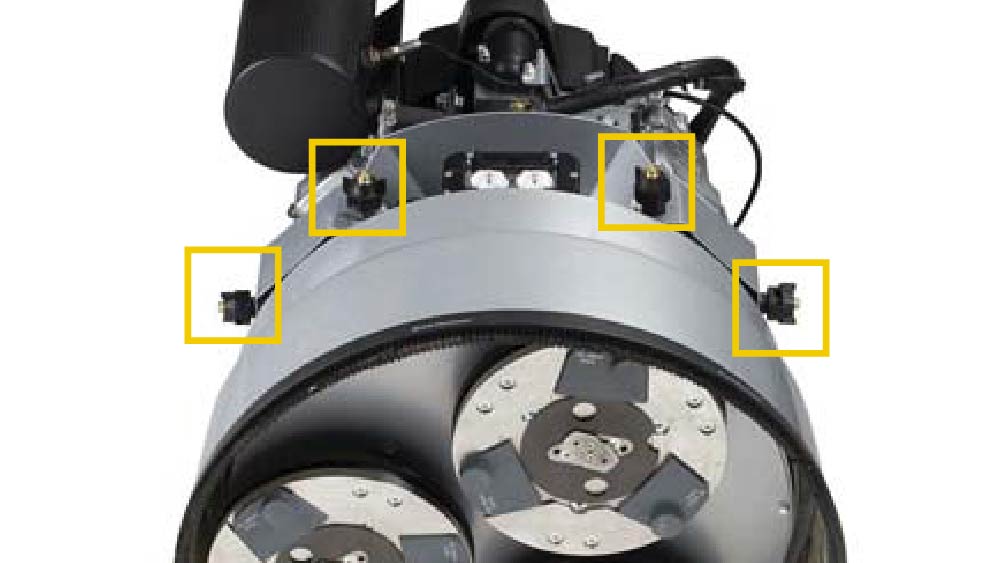

In search of a more effective solution to the silica dust problem, Superabrasive turned to Pumptec. They wanted a way to integrate a misting system into their concrete grinding equipment. Our engineers helped design a system with a nozzle size appropriate for their desired flows and pressures. The misting system comprises four .006 nozzles around the outside of the base of the unit creating a “dust curtain.” An adjustable 50-1000 PSI system allows for precise pressure adjustments to specific nozzles.

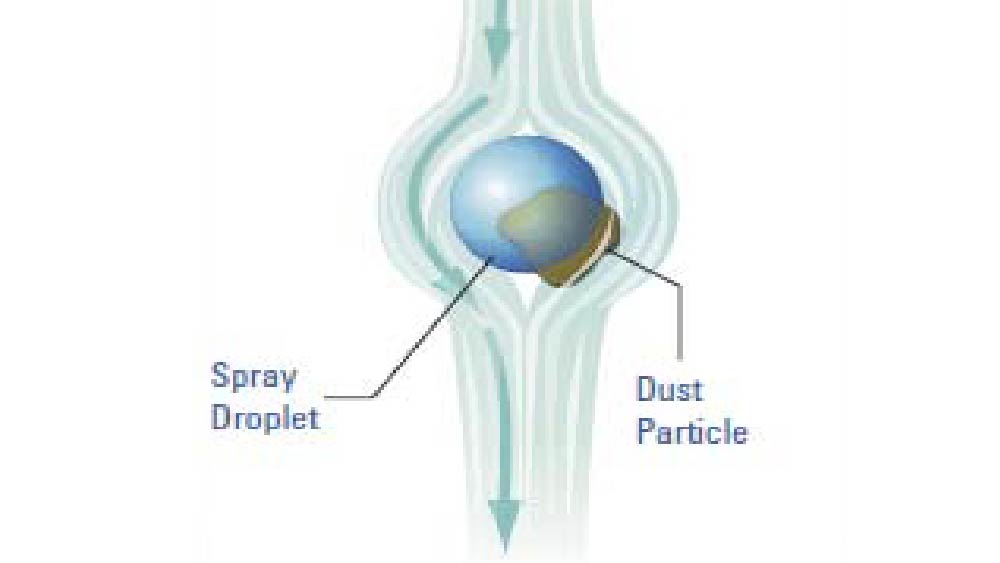

The mist produces a droplet size that matches that of the silica dust; encapsulating it and holding it to the ground instead of allowing it to become airborne. Its flow is low enough for suppressing the dust without creating a silica slurry on the ground and yet is high enough to allow the grinders to run a secondary larger nozzle for wet grinding with the simple turn of a ball valve.

With the new “dust curtain” system in place, Superabrasive saw a dramatic increase in sales and is now considered the leading innovator in the concrete grinding industry.

700 McKinley Street

Anoka, MN 55303

Phone: (763) 433-0303

Fax: (763) 433-0404

Toll Free Fax: (888) PUMPTEC