The Link Between Pest Control Pump Precision & EPA Compliance

Shawn Glover, VP of Sales, Aug 23, 2023

The Environmental Protection Agency (EPA) has hundreds of pest control and pesticide-related regulations and recommendations.

Commercial pest control companies, in particular, need to protect their workers, the environment, and their livelihoods by ensuring the chemicals they use are in compliance and compatible with the job at hand. A big part of EPA compliance is ensuring that pump equipment disperses those chemicals safely, reliably, and accurately.

We get a lot of questions from pest control pump manufacturers and operators regarding our pump equipment and whether it can help them not only sustain the environment, but sustain their profit margins, too. Read more to get answers to our most frequently asked questions.

What is the ideal flow and pressure (GPM and PSI) for pest control?

Determining the proper pest control GPM and PSI will depend on the application. Commercial mosquito misters, for example, require low flow and high pressure (up to 1.25 GPM at 300 PSI or higher). Combined with the right adjustable nozzles, it will result in an ultra fine mist with ideal droplet sizes.

A commercial lawn care pump or soft wash pump that treats lawns or pests over a broad area or on eaves of a house, however, will generally require higher flow and lower pressure (up to 6.8 GPM and 300 PSI) to reach surfaces. Some pest control applications don’t require such coverage, and may require less flow.

READ MORE: The Importance of Getting Flow & Pressure Right

Which type of pump is the most precise for pest control?

Overspray of chemicals is a major problem in the lawn care and pest control industry. According to the EPA, the majority of unintended wildlife killings result from improper use of lawn chemicals, which can include pesticides. Not only can overspraying cause environmental damage and risk noncompliance, wasting chemicals is costly.

While getting the GPM and PSI right is the first step, maintaining consistency and accuracy from the moment an operator pulls the trigger until they release it is critical. Fluctuating pressure often results in chemicals shooting out of a gun at inconsistent rates. In the case of mosquito misters that cycle on and off, inconsistent flow and pressure will result in larger droplet sizes that can leave a wet film or fail to disperse into the air properly.

Pumptec plunger pumps are positive displacement pumps, allowing for precise control of fluids being drawn into and moved through the system at a consistent rate. Because they use a rigid plunger or piston, their flow remains steady. Diaphragm pumps are also considered positive displacement pumps, but because they have flexible membranes as part of their design, their flow can fluctuate and be inconsistent.

Plunger pumps are the best way to ensure precise application of chemicals. Accessories can also play an important role in maintaining consistent flow and pressure. The use of pulse hoses further mitigates pulsation, and variable-speed flow controllers allow pump operators to adjust the output of a high-pressure pump to achieve ultra-precise coverage.

READ MORE: Top 5 Features to Look For in Pest Control Pumps

Are battery-powered pest control pumps as good as gas-powered pest control spray pumps?

In addition to improper use of chemicals, many pest control pump operators have another environmental concern: Small gas-powered engines, like those used in pest control, are coming under increased scrutiny and are even being banned in some states.

Most operators would prefer a 12VDC electric pump for its environmentally friendly footprint, its compact size, lower maintenance costs, safety, longevity, and lower total cost of ownership. However, they’re concerned it won’t hold a battery charge long enough or won’t have enough power.

This is where a plunger pump has a distinct advantage over other battery-operated pest control pump sprayers. Pumptec plunger pumps are inherently efficient, able to achieve 90-93% efficiency, and they draw fewer amps than diaphragm or rotary vane pumps. Not only can Pumptec plunger pumps hold a charge all day for most applications (and be charged in between jobs as needed so they’re ready for the next), they can also deliver the flow and pressure required to get the job done.

Gas-powered engines can, undoubtedly, deliver more flow, but the reality is that too much flow can run the risk of overspray and noncompliance with EPA standards. Most gas-powered pumps are overkill. It’s much more important to achieve precise GPM and PSI that is right-sized for the application.

A leading pest control company, Terminix, discovered firsthand how versatile, powerful, and reliable a battery-powered pest control pump could be. They were able to move away from fossil fuels without losing performance. Be sure to check out their case study below.

What are the best commercial pest control pump sprayers?

Here at Pumptec, we’ve collaborated with commercial pest control experts to design several pumps to suit their needs. Not only do they deliver the right balance of flow and pressure, they’re also highly compatible with harsh chemicals.

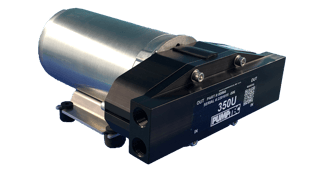

Our 350U plunger pump features a 12V DC motor designed specifically for the pest control industry, delivering 2.6 GPM and 200 PSI at 30 amps.

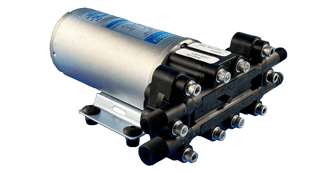

For applications requiring greater horizontal and vertical throw, our 12V DC X-Series plunger pump also draws 30 amps and delivers up to 6.8 GPM and up to 300 PSI.

For mosquito misting, we recommend our 114T Series Pump with 120 Volt M70 motor, delivering 300 PSI and up to 1.25 GPM. It can be customized to precise rates.

For mosquito misting, we recommend our 114T Series Pump with 120 Volt M70 motor, delivering 300 PSI and up to 1.25 GPM. It can be customized to precise rates.

Complying with EPA standards requires in-depth industry knowledge and using the right equipment. At Pumptec, we care about the environment and our customers, and are here to help you configure a pump to meet your specifications. Contact our team of pump experts today, and remember to check out the Terminix Case Study showing how we helped them achieve their sustainability goals and lower operating costs.